Stress Containers: Kinds, Applications, Advantages And Things To Consider

Stress storage tanks play a critical duty in keeping constant water stress in your house's pipes system. They are important elements of well water systems, ensuring that the water pump does not cycle on and off as well frequently, a scenario which can lead to early wear. The dimension of the stress container is vital for effective system performance, and disregarding this element can cause multiple concerns. These elements play a critical duty in keeping regular water stress throughout your system, making sure a trustworthy water system. These systems can offer consistent stress and enhance pump operation, but they need cautious factor to consider when figuring out tank dimension.

Connect pipes and installations to connect the tee suitable to the pressure storage tank's inlet and outlet ports. If you're mounting the same brand name and model of stress storage tank that you had before, installment is a breeze. If all the pipes remain in good problem, you can simply glide your new stress tank in and attach it.

Since 1970, many personal water systems have actually utilized bladder-type stress containers. The bladder is a bag typically made of butyl rubber or adaptable polyvinyl chloride. The water is included in the bladder and does not come in straight contact with air in the container. The bladder holding the water expands right into the pressurized air area in the tank as it is filled up. As water is used from the system, the bladder falls down up until the water is virtually cleared before the minimal pressure is reached, activating the pump.

Davey Supercell 100 Litre Stress Tank

Remember, well pressure storage tank installment might vary depending upon the certain supplier's instructions and the style of your well water supply. Before turning on the well pump, established the stress in the container to the desired pre-charge pressure. This is normally a few psi listed below the stress switch's "cut-in" pressure. Follow the steps listed below meticulously to avoid improper installation or damage to your pressure storage tank or well system. Appropriate sizing of a stress container influences functionality and enhances the durability of the system. Improperly sized storage tanks can cause frequent biking and possible damage.

- Hot water containers may have a gas or oil heater system in addition to electric immersion heating units.

- Along with typical household tools, you'll also need to shut off the water and electrical power materials to the well.

- Hello there Gary, there are a great deal of variables to take into consideration concerning your specific system to state absolutely.

- The number of fittings also comes in to play as each suitable causes friction loss.

- A captive air tank has a rubber or plastic membrane separating the water from the air, and should be pre-charged to a particular stress, typically 2 psi listed below the pressure switch cut-in factor.

The within the cover has a specifications sticker label showing the cut-on and cut-off stress. Link a yard hose pipe to the stress container's drainpipe shutoff bib at the bottom of the storage more info tank. When the water stress in the tank gets to the cut-out pressure, the stress button turns the pump off. The pressure switch is utilized pressure tanks to immediately switch the pump on and off. The first stress setup is called the cut-in pressure while the second pressure is called the cut-out stress. A well pump is in charge of pumping water from the well to the pressure tank, while a check prevents water from receding, or out of the stress container to the well.

Is 100 Psi Water Pressure Expensive?

In conclusion, the distinction between containers and stress vessels depends on their design, functionality, and desired applications. Containers mainly function as storage vessels for fluids, with different materials such as steel and plastic used relying on the kept substance. They are available in different types like bladder containers, diaphragm storage tanks, and air-over-water tanks, each customized to certain requirements.

- Bigger storage tanks can keep much more air, allowing for longer operational durations before the compressor motor needs to unwind in and replenish the storage tank.

- Installation other than the advised might lead to damage to the tank and loss of capability.

- Hydrogen part failures resulting in external leakages create a threat which can result in fire or explosion.

- It's vital to make sure that the tank fulfills the requirements of Pressure Tools Regulation or American Culture of Mechanical Designers for safety and efficiency.

- The material made use of to coat the tank and prevent corrosion is described as "glass lined" or "epoxy coated."

A pressure vessel made use of for The Boeing Business's CST-100 spacecraft. A tapered string supplies easy setting up, however requires high torque for attaching and causes high radial forces in the vessel neck. All cylinders constructed for 300 bar working stress, all diving cylinders, and all composite cyndrical tubes utilize identical threads. Stress vessels may be lined with numerous metals, porcelains, or polymers to avoid leaking and secure the structure of the vessel from the had tool. This liner might also bring a significant part of the pressure tons.

The bladder is a huge balloon loaded with air that agreements and expands, causing the pump to trigger. They don't have the troubles of a solitary chamber or a diaphragm tank because they're self-contained. One more advantage is that due to the fact that the air and water are maintained different, the air is not absorbed into the water and therefore no extra air is needed. It is needed to be reliable in extreme setups, this is just one of one of the most substantial qualities of a pressure vessel.

By taking in pressure rises, these containers lengthen the life of your pump and guarantee it operates more efficiently. Made with toughness in mind, these storage tanks can hold up against varying stress and problems. Whether you're wanting to enhance a house pump system or boost the performance of a commercial piston pump, our variety of stress storage tanks offers the ideal service. Explore our collection to locate the best pressure container that fits your requirements, and experience the difference in efficiency and durability in your pump system. As with all GWS items Challenger ™ storage tanks are high quality tested throughout the production procedure to guarantee their structural honesty. Upkeep totally free, these tanks are the most effective steel pressure vessels on the marketplace today, and stand for a budget-friendly solution.

As an outcome of the plant's high warmth rate, a when via boiler or a single drum central heating boiler is a lot more viable. Bi drum central heating boilers are thoroughly used in process vapor generation because they can adapt to high load variation and reply to load variants. On top of the water tubes, there is a reservoir of water/steam. The drum gathers the vapor generated by the water tubes and works as a stage separator for the water/steam mix. Develop of hotter water is helped by the thickness differential in between cool and warm water. Stress relief valves are utilized as a safety and security attribute while running.

Jonathan Taylor Thomas Then & Now!

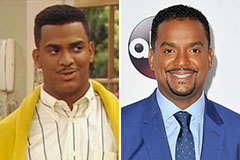

Jonathan Taylor Thomas Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!